Just How Epoxy Injection Molding Improves Product Quality: A Take A Look At Its Advantages and Uses

Epoxy injection molding stands out for its special benefits when it comes to boosting product high quality. You'll discover that this procedure not just develops high-strength, lightweight parts yet also allows for intricate layouts and remarkable surface finishes. What truly sets epoxy injection molding apart in numerous industries? Let's check out the essential benefits and applications that make it a necessary choice for suppliers today.

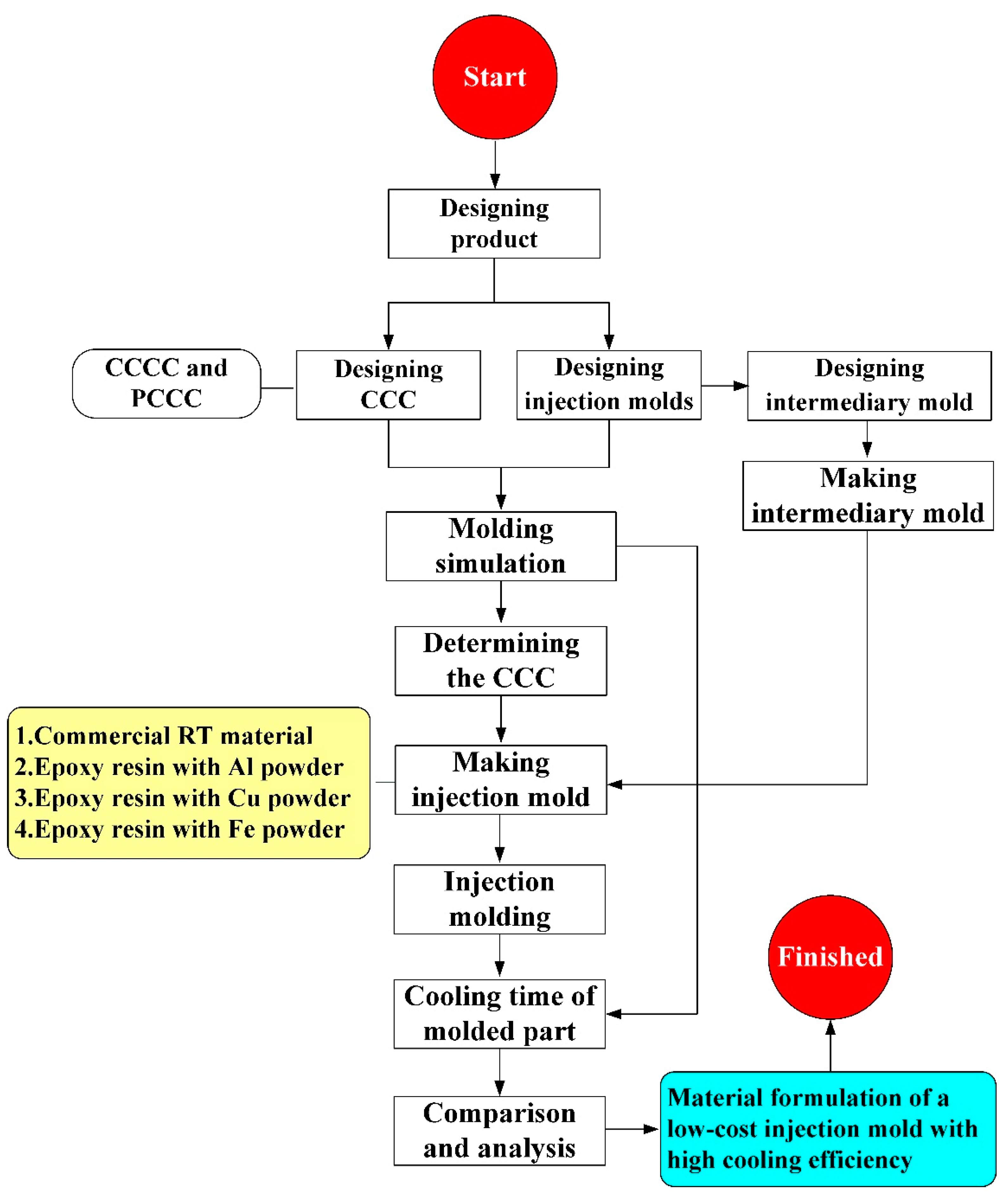

The Basics of Epoxy Shot Molding

Epoxy injection molding is a remarkable procedure that incorporates accuracy and versatility to produce long lasting components. You start by mixing epoxy resin with a hardener, which starts a chain reaction, leading to a strong material. The mixture's viscosity enables it to move quickly into mold and mildews, catching detailed information and complex shapes.Once the epoxy is infused right into the mold and mildew, it treatments under controlled temperature and stress, guaranteeing a solid bond and excellent structural integrity. You can adjust the formulation, allowing for enhanced residential properties such as boosted resistance to chemicals or boosted thermal stability.This procedure is specifically useful for producing complex parts used in different sectors, consisting of automotive, aerospace, and electronic devices. By leveraging epoxy injection molding, you're able to attain top notch, lightweight parts that satisfy strict efficiency demands. Overall, comprehending the essentials of this molding strategy sets the structure for valuing its more comprehensive applications and benefits.

Secret Benefits of Epoxy Shot Molding

While discovering the crucial benefits of epoxy injection molding, you'll locate that its ability to generate high-strength, lightweight parts stands out. This process enables detailed layouts and complicated geometries that conventional molding approaches struggle to achieve. With epoxy injection molding, you can expect a high level of precision and consistency in every set, guaranteeing that your items meet limited specifications.Another advantage is the fast curing time, which speeds up production and minimizes expenses. You won't have to wait wish for your elements to establish, enabling faster job timelines. Additionally, the versatility of epoxy formulations implies you can tailor residential or commercial properties like thickness and setup time to match your certain needs.Lastly, epoxy injection molding uses superb surface coatings, which can boost the aesthetic charm of your items and decrease the demand for additional completing processes. In general, this approach offers a trustworthy service for numerous applications throughout multiple sectors.

Enhanced Longevity and Stamina

You profit from boosted longevity and toughness in your elements when you pick epoxy injection molding (epoxy injection molding). This process makes use of high-performance epoxy resins that develop durable parts efficient in holding up against harsh problems. You'll find that these elements withstand deterioration far better than those made from typical materials.The solid molecular structure of epoxy supplies outstanding adhesion, guaranteeing that your product maintains stability over time. You can anticipate improved resistance to chemicals, dampness, and temperature fluctuations, which contributes to the durability of your items.Additionally, epoxy shot molding allows for precise control over the density and density of the parts, even more boosting their strength. This suggests you get lightweight yet extremely long lasting elements that won't jeopardize on efficiency. By spending in epoxy shot molding, you're guaranteeing that your items are constructed to last, giving satisfaction and boosting total high quality

Convenience Across Industries

Epoxy shot molding reveals its adaptability in various markets, from the vehicle industry to customer electronics and medical tool production. You'll locate it plays a crucial duty in developing durable components that satisfy details needs. This versatility not only enhances item performance yet likewise opens ingenious opportunities throughout these industries.

Automotive Industry Applications

Consumer Electronics Innovations

While the vehicle industry benefits substantially from epoxy injection molding, the consumer electronic devices sector likewise reaps its incentives through ingenious applications. You'll discover that epoxy injection molding improves the resilience and efficiency of various digital parts, from circuit boards to rooms - epoxy injection molding. Its capacity to develop lightweight yet strong components helps in developing sleeker gadgets, making them much more attractive to customers. Additionally, the precision of this molding strategy guarantees that intricate styles are consistently duplicated, which is essential for modern tools. This flexibility allows producers to trying out brand-new styles without endangering top quality. By embracing epoxy injection molding, you'll be empowering your items to stand out in an open market, driving advancement and customer fulfillment

Medical Gadget Manufacturing

When it involves clinical tool manufacturing, the advantages of epoxy injection molding are hard to forget. You'll discover that this strategy permits precise control over product residential or commercial properties, making sure that tools fulfill rigorous wellness criteria. The toughness and chemical resistance of epoxy make it suitable for items that should hold up against sterilization procedures. Plus, the capacity to develop complex layouts boosts performance while maintaining prices down. With faster production cycles, you can bring ingenious medical options to market faster. Whether you're establishing surgical instruments or analysis tools, epoxy shot molding offers convenience that satisfies the distinct demands of the medical field. Accepting this technology can significantly enhance your product quality and reliability in healthcare applications.

Cost-Effectiveness and Efficiency

Offered the rising prices of materials and manufacturing, epoxy shot molding stands out as a cost-effective service for manufacturers. This technique permits you to lessen waste and reduce material costs, as it efficiently uses epoxy material to create accurate parts. With its capacity to create complicated forms in one pass, your manufacturing time decreases significantly, resulting in faster turnaround times.Moreover, epoxy shot molding enhances your manufacturing efficiency. The procedure requires much less power compared to typical approaches, which aids lower functional expenses. You'll locate that the longevity of the end products likewise implies fewer repair work and replacements, conserving you cash over time.

Environmental Considerations

As problems concerning environmental impact expand, epoxy injection molding uses an extra sustainable manufacturing option. This procedure usually produces much less waste than typical approaches, permitting you to make best use of product usage. By using thermosetting polymers, epoxy injection molding generates solid, durable items that commonly require much less constant replacement, which decreases overall consumption and waste.Moreover, epoxy materials can be formulated to reduce volatile organic substances (VOCs), reducing unsafe exhausts throughout manufacturing. You'll likewise discover that the power performance of this technique can bring about lower carbon impacts compared to various other manufacturing processes.Additionally, several epoxy solutions are recyclable, giving you the possibility to repurpose products instead of sending them you could check here to garbage dumps. By selecting epoxy shot molding, you're not just improving item high quality; you're also making a responsible choice for the environment, aligning your production methods with sustainability objectives.

Future Patterns in Epoxy Shot Molding

As you look in advance in epoxy shot molding, you'll notice interesting advancements in material advancement that boost efficiency and toughness. Automation is established to enhance performance, making processes much faster and a lot more economical. And also, incorporating sustainable methods will aid meet expanding environmental demands while maintaining high quality.

Advanced Materials Growth

While the typical applications of epoxy injection molding have currently verified effective, emerging fads in advanced products advancement are established to revolutionize the sector (epoxy injection molding). You'll discover that scientists are currently concentrating on including nanomaterials and bio-based materials right into epoxy formulas, improving residential or commercial properties like strength, versatility, and thermal resistance. These innovations not just enhance product efficiency but also minimize ecological influence. As you check out these developments, you'll find that integrating wise materials can lead to self-healing capacities and flexibility in numerous problems. With these advancements, you'll be able to produce items that satisfy the demands of contemporary consumers while pressing the limits of what epoxy shot molding can attain. It's an amazing time to be entailed in this transformative field!

Automation and Performance

With the increase of automation in manufacturing, epoxy injection molding is set to become a lot more effective than ever before. You'll observe that automated systems simplify procedures, reducing human error and enhancing accuracy. This innovation permits faster production cycles, which indicates you can satisfy demand without sacrificing high quality. Robotics and advanced software program are progressively being integrated right into the molding procedure, enabling real-time surveillance and changes. You'll find that these developments not only enhance uniformity but likewise optimize material use, decreasing waste. As automation proceeds to advance, you can expect also greater degrees of efficiency and productivity. Embracing these improvements will certainly place you at the center of the market, guaranteeing your products remain affordable in a swiftly altering market.

Lasting Practices Assimilation

Integrating lasting practices right into epoxy injection molding is coming to be necessary for organizations intending to reduce their ecological influence. You can begin by sourcing eco-friendly materials and using recycled web content in your products. This not just decreases waste but also interest eco mindful customers. Applying energy-efficient machinery and optimizing manufacturing procedures can further decrease your carbon footprint.Additionally, consider embracing a closed-loop system to reuse waste and click here to find out more reduce material use. Frequently reviewing your supply chain for sustainability can likewise help you make informed choices that line up with green objectives. By embracing these techniques, you'll not just improve your brand's reputation however also add to a much healthier world, setting a favorable example in the sector for future generations.

Frequently Asked Questions

What Sorts of Products Are Frequently Made With Epoxy Injection Molding?

You'll find epoxy injection molding commonly utilized for automotive parts, digital components, medical gadgets, and different commercial applications. Its flexibility permits you to develop resilient, specific products that satisfy diverse practical needs successfully.

How Does Epoxy Compare to Other Molding Materials?

You'll discover it uses superior strength, resilience, and chemical resistance when you compare epoxy to other molding products. It's also less prone to warping, guaranteeing your products preserve their honesty under different problems.

Can Epoxy Shot Molding Be Made Use Of for Small-Scale Manufacturing?

Yes, you can definitely utilize epoxy injection molding for small-scale production. It uses accuracy and flexibility, making it optimal for producing elaborate styles while maintaining excellent quality, which is crucial for customized projects and prototypes.

What Is the Normal Preparation for Epoxy Injection Molded Parts?

Normally, you can anticipate a preparation of 4 to 6 weeks for epoxy shot molded components. Variables like design tooling, intricacy, and manufacturing quantity can affect this timeframe, so strategy accordingly.

Exist Particular Precaution for Handling Epoxy Materials?

Yes, there specify safety procedures for taking care of epoxy materials. You need to use gloves, safety glasses, and a mask to prevent skin get in touch with and breathing. Always operate in a well-ventilated location to lower exposure risks. When it comes to improving item high quality, epoxy injection molding stands out for its distinct advantages. With epoxy shot molding, you can anticipate a high level of precision and uniformity in every set, guaranteeing that your items meet tight specifications.Another benefit is the quick curing time, which speeds up production and reduces prices. In addition, the adaptability of epoxy formulas indicates you can tailor residential properties like viscosity and setup time to match your certain needs.Lastly, epoxy shot molding supplies superb surface coatings, which can enhance the aesthetic allure of your products and minimize the have a peek at this website need for second finishing procedures. By using thermosetting polymers, epoxy shot molding generates strong, resilient products that commonly need less frequent substitute, which reduces total usage and waste.Moreover, epoxy materials can be formulated to minimize volatile natural compounds (VOCs), reducing unsafe discharges throughout production. With these advancements, you'll be able to develop items that fulfill the demands of modern consumers while pressing the borders of what epoxy shot molding can accomplish.